The Department of Architecture at the College announces seminars Nos. 18, 19, and 20 for this year.

The Department of Architecture at the Faculty of Engineering announces seminars Nos. 18, 19, and 20 for this year.

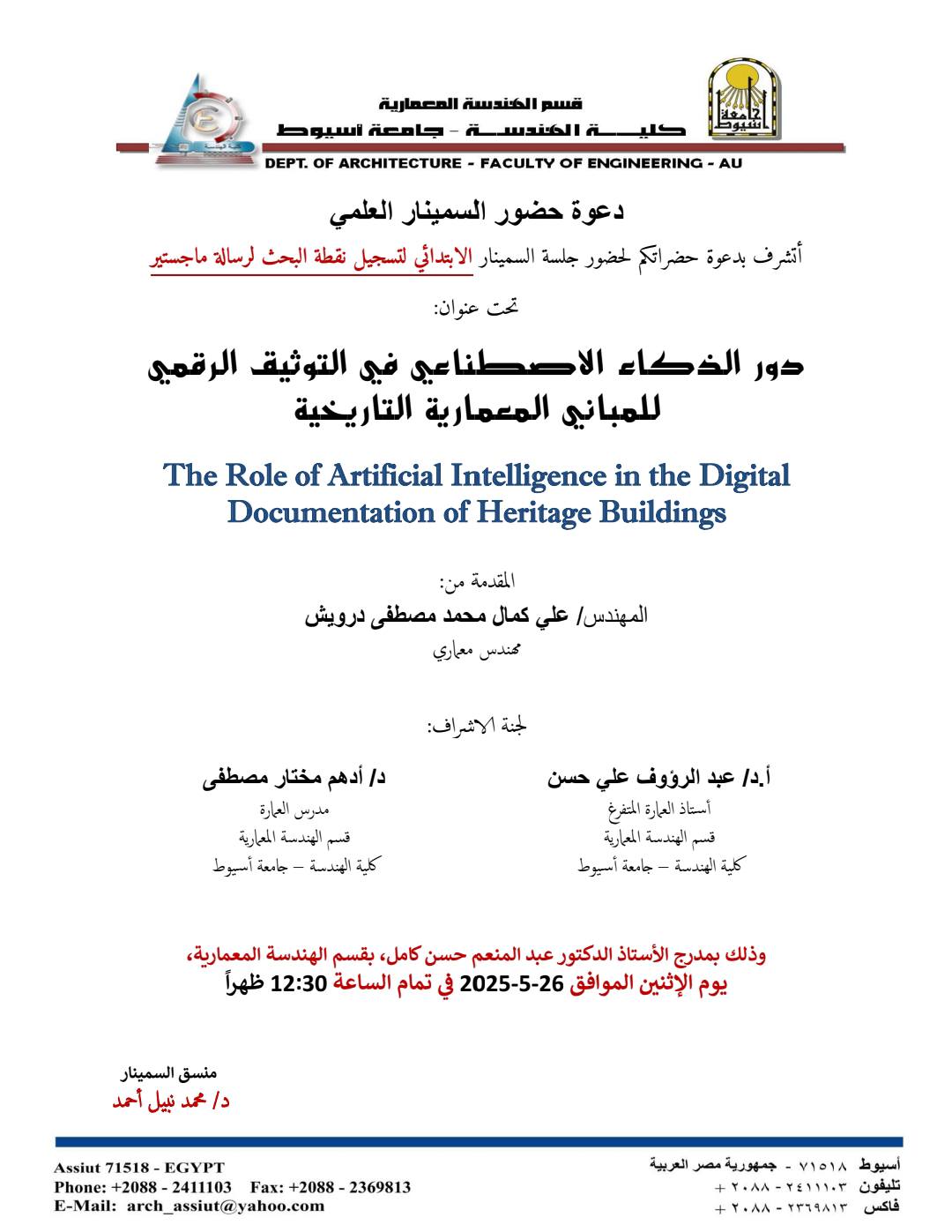

Seminar No. 18 (2024-2025)

Introductory seminar to record the research point for the master's thesis of Engineer Ali Kamal Darwish

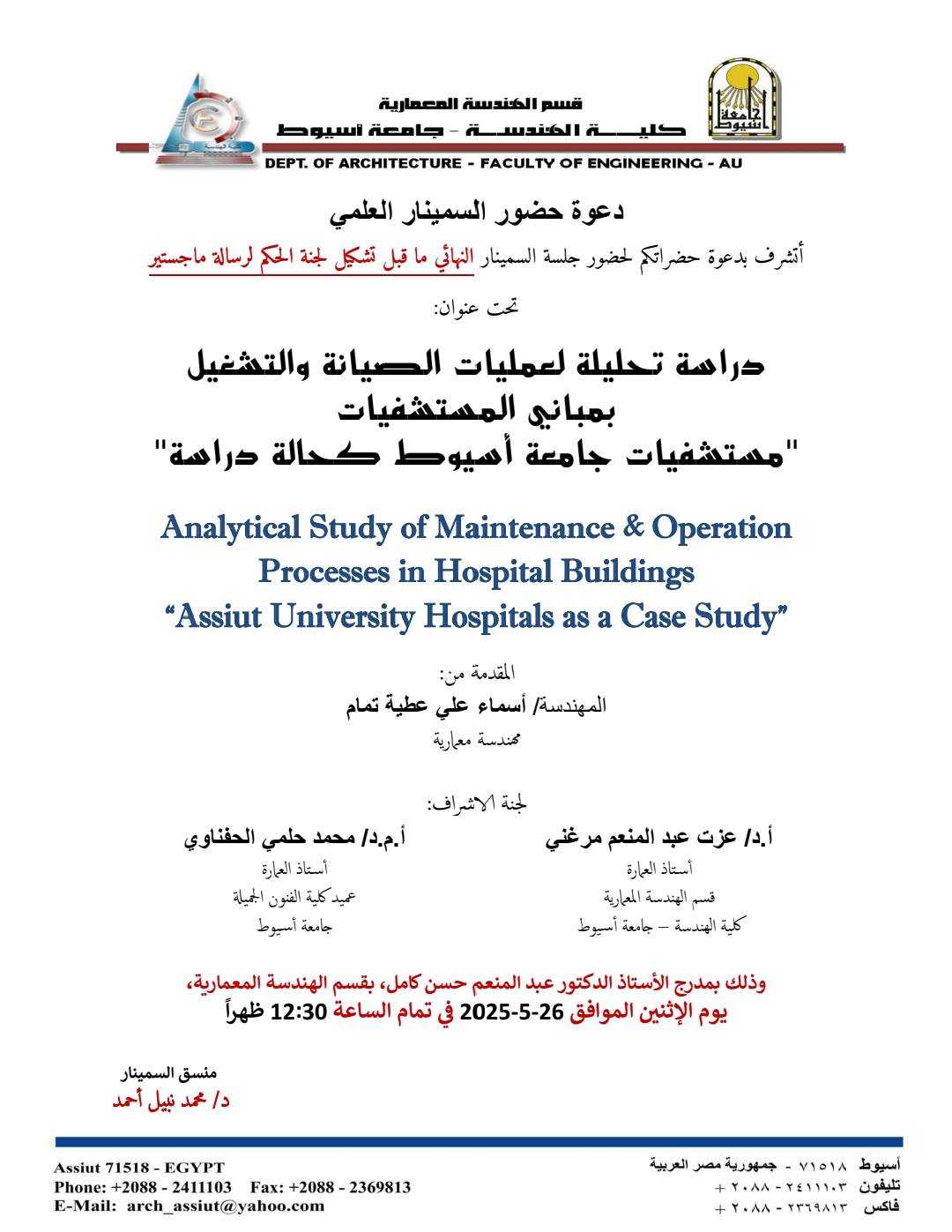

Seminar No. 19 (2024-2025)

Final seminar before forming the jury for the master's thesis of Engineer Asmaa Ali Attia

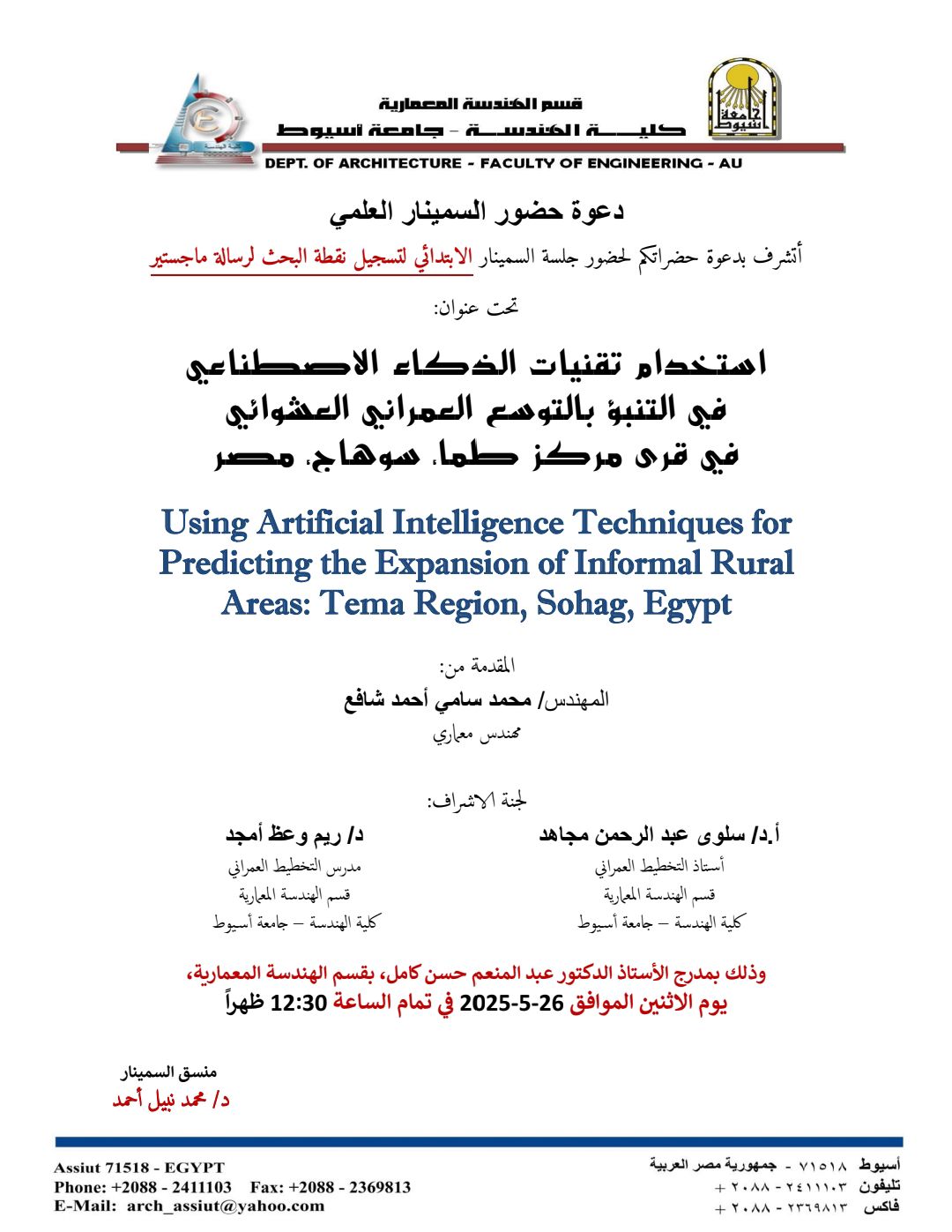

*Seminar No. 20 (2024-2025)

Introductory seminar to record the research point for the master's thesis of Engineer Mohamed Sami Shafea

This will be held on Monday, May 26, 2025, starting at 12:30 PM, in the auditorium of Professor Abdel Moneim Hassan Kamel, Department of Architecture.

بالانابة عن ادارة الكلية وجميع منتسبيها، ينعي الاستاذ الدكتور خالد صلاح عميد الكلية الاستاذ الدكتور اسامة الجنايني .. الاستاذ المتفرغ بقسم هندسة التصميم الميكانيكي والإنتاج بالكلية.. ويتقدم بخالص التعازي والمواساة لأسرة الفقيد، ولجميع منتسبي اقسام الهندسة الميكانيكيةبالكلية.

بالانابة عن ادارة الكلية وجميع منتسبيها، ينعي الاستاذ الدكتور خالد صلاح عميد الكلية الاستاذ الدكتور اسامة الجنايني .. الاستاذ المتفرغ بقسم هندسة التصميم الميكانيكي والإنتاج بالكلية.. ويتقدم بخالص التعازي والمواساة لأسرة الفقيد، ولجميع منتسبي اقسام الهندسة الميكانيكيةبالكلية.